What is Total Cost of Ownership (TCO)?

In the fast-paced world of modern manufacturing, maintaining the optimal performance of your equipment is paramount. Understanding the Total Cost of Ownership (TCO) for your equipment is a critical factor that can make or break the success of your businesses.

INTRODUCING TCO

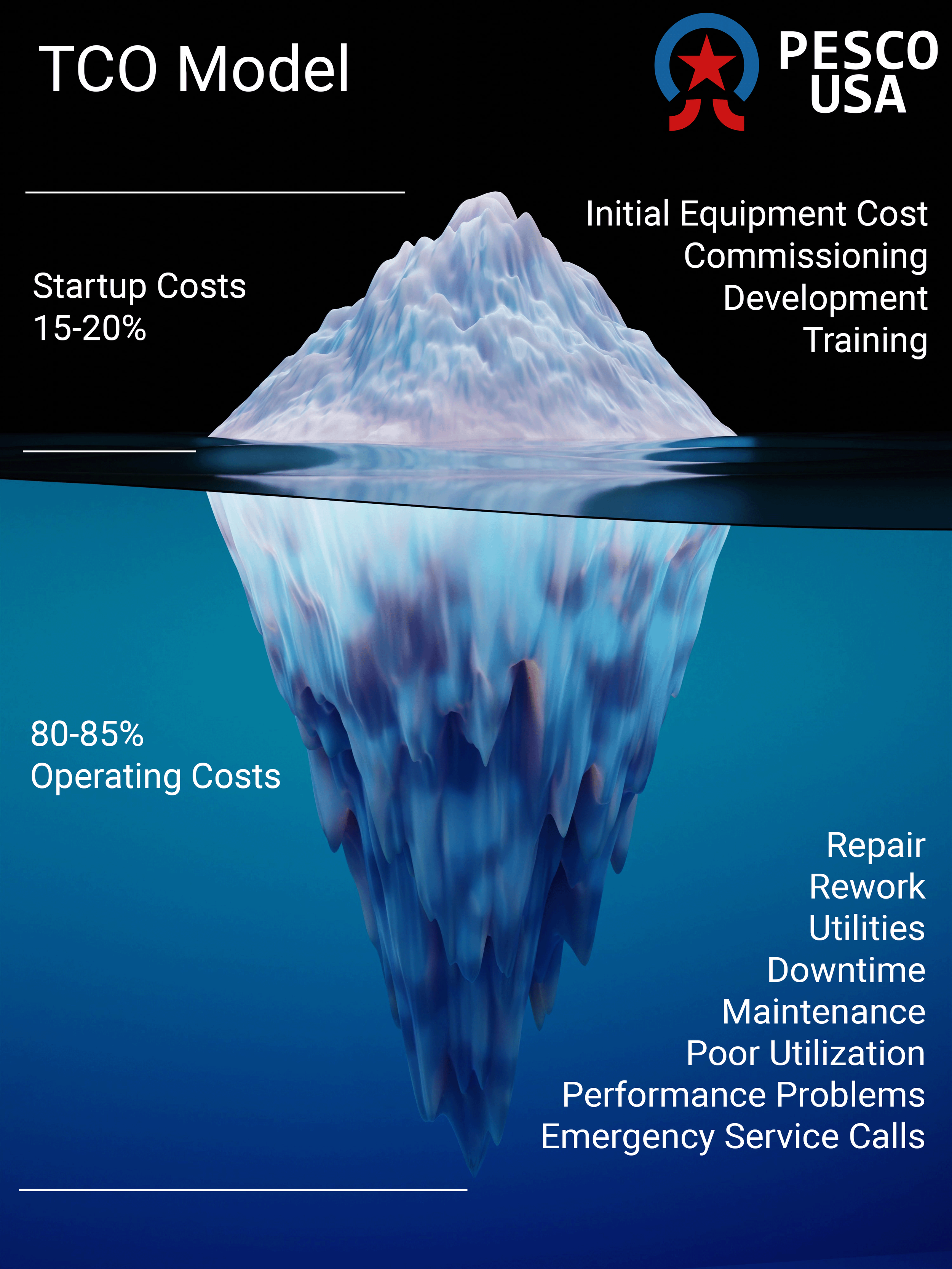

TCO encompasses all costs associated with owning and operating equipment throughout its entire lifecycle. It goes beyond the initial purchase price and takes into account factors like maintenance, repairs, energy consumption, and even the potential impact of downtime on production. By focusing on equipment line health, implementing effective Lifecycle Management strategies, and practicing resource management, businesses can achieve a healthier bottom line, enhanced ROI, and smoother operations.

What is Line Health?

Maintaining equipment line health is not just about fixing issues when they arise; it's about implementing a comprehensive strategy that ensures efficiency, longevity, and cost-effectiveness. TCO considers not only direct costs like maintenance and repairs but also the indirect costs tied to downtime, production delays, and potential safety risks. Prioritizing line health through proactive maintenance ensures consistent performance, minimizing disruptions and ultimately leading to enhanced productivity. Regular inspections, predictive analytics, and strategic upgrades are all part of this approach.

What is Lifecycle Management?

At the heart of TCO lies the concept of Lifecycle Management. It's not just about the initial purchase cost of equipment; rather, it encompasses all costs associated with the equipment throughout its entire lifespan. This holistic approach includes acquisition, installation, maintenance, operational costs, and even disposal expenses. By taking into account all these factors, businesses can make informed decisions that lead to higher ROI.

What is MTBF?

One of the key indicators to consider in TCO analysis is Mean Time Between Failures (MTBF). This metric gauges the reliability of equipment by calculating the average time it operates before a failure occurs. By understanding MTBF, businesses can fine-tune their maintenance schedules, minimizing unplanned downtime and optimizing resource management. Instead of reactive approaches to maintenance, adopt proactive strategies that save time and money in the long run. Investing in quality maintenance and genuine replacement parts reduces the frequency of failures and enhances overall reliability.

What is Resource Management?

Resource management is another area where TCO shines. By analyzing TCO, businesses can allocate resources judiciously. Allocating resources efficiently involves optimizing manpower, spare parts inventory, and scheduling maintenance activities. By streamlining these processes, businesses can minimize downtime and reduce the costs associated with extended interruptions to operations. By strategically planning for maintenance, upgrades, and replacements based on TCO insights, businesses can avoid sudden expenses and costly emergency repairs.

What is ROI?

Return On Investment (ROI) is a key metric for any business, and TCO plays a pivotal role in its calculation. While the initial cost of equipment might seem high, factoring in TCO provides a clearer picture of the long-term financial impact. By analyzing the full range of costs associated with ownership, including maintenance, repairs, energy consumption, and potential downtime, businesses can make more informed decisions about the equipment's actual profitability over time. TCO analysis helps prevent underinvestment in maintenance and overinvestment in unnecessary upgrades, striking the right balance to ensure smooth operations without draining financial resources.

What does it all mean?

By considering the full scope of costs using TCO, businesses can make informed decisions that ultimately lead to a higher Return On Investment (ROI) and better resource management by shifting from reactive repairs to proactive planning & maintenance. Investing in proactive maintenance and comprehensive TCO analysis is an investment in sustained success in today's competitive landscape. Just remember, TCO isn't just about the bottom line; it's about managing production as efficiently as possible while keeping productivity moving forward.